Do you think this article is going to accuse you of contributing to environmental harm by drinking pineapple juice? Not at all! Enjoying a can of pineapple juice, or even apple juice, once a day doesn’t make you a culprit. But have you ever wondered what happens to all the waste created in the process—like the peels, cores, and pulp? The reality is, with large-scale production, tons of pineapple waste are generated. Fortunately, innovative minds have stepped in to tackle this issue, turning what was once discarded into sustainable products that benefit both the environment and consumers.

In this article, we’ll explore how sustainable practices are transforming the pineapple juice industry, and highlight some incredible ways companies are repurposing waste to create eco-friendly solutions. Whether it’s generating renewable energy or crafting eco-conscious textiles, the future of pineapple juice production is looking greener than ever!

Canned Pineapple Juice: A Growing Sensation in the Beverage World

The production of pineapple juice on a global scale is enormous. Countries like Thailand, the Philippines, and Costa Rica are major players in the industry, producing millions of tons of pineapple annually. Pineapple juice isn’t just consumed as a drink, either; it’s used in cocktails, smoothies, marinades, and even desserts. With this rise in consumption comes a hidden issue: waste. Peels, cores, and unused flesh account for more than half of the pineapple’s weight, often discarded or left to decompose.

In a similar context, pineapple juice manufacturers are grappling with the same issue, where pulp and skins are wasted despite having significant value. But just like the growing efforts in sustainability to reuse byproducts, the juice world is catching up with innovative solutions to manage waste effectively.

Turning Waste from Canned Pineapple Juice Production to Value

Several innovative startups are stepping in with new technologies that offer creative ways to repurpose pineapple waste, moving toward a zero-waste model in food production.

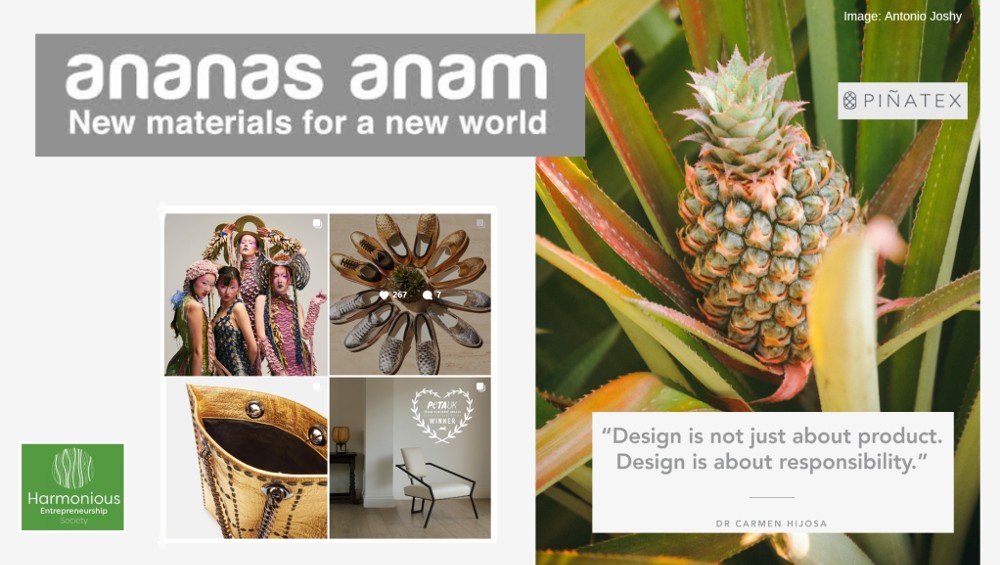

1. Piñatex: Pineapple Leaves into Sustainable Textiles

Piñatex by Ananas Anam, is a well-known sustainable textile made from the fibers of pineapple leaves. This material serves as an eco-friendly leather alternative and global fashion brands has been using this for products like bags, shoes, and even upholstery. Piñatex has contributed to reducing agricultural waste and offering a sustainable option for industries that traditionally rely on animal leather or synthetic materials. The production process aligns with circular economy principles, turning pineapple leaf waste into a high-value, durable product.

2. Biogas from Pineapple Residue: BioFactory Innovations

In the realm of renewable energy, companies like BioFactory are transforming pineapple waste—such as skins and cores—into biogas through anaerobic digestion. This process creates methane gas – a natural fuel to generate electricity or heat, offering a clean alternative to fossil fuels. BioFactory’s technology is particularly relevant for pineapple juice manufacturers, who generate large amounts of organic waste. By turning this waste into energy, they contribute to a more sustainable, energy-efficient production cycle.

3. Composting and Fertilizers: FruitLeather Rotterdam

FruitLeather Rotterdam is taking the concept of composting to the next level by converting leftover pineapple pulp and skins into both organic compost and leather-like material. The compost produced from this waste helps enrich the soil, promoting healthier crops without relying on chemical fertilizers. FruitLeather also converts some of the waste into a durable, vegan-friendly leather, further reducing the environmental impact of pineapple production. Their innovative approach highlights how we can recycle and repurpose waste into eco-friendly materials.

4. Pineapple Vinegar

Kucheza Vinegars specializes in creating artisanal vinegars, including pineapple vinegar, made from the skins and cores of the fruit. Instead of discarding these byproducts, Kucheza uses them in a fermentation process to produce a rich, tangy vinegar that is popular in cooking, cleaning, and even skincare. This brand shows how responsible business can transform wastes into a premium, sustainable product that consumers can use in multiple ways, reducing the environmental footprint of the juice industry.

Why Sustainable Practices Matter in Manufacturing Canned Pineapple Juice

With growing awareness of the environmental impact of large-scale juice production, pineapple juice manufacturers are looking for ways to cut down on waste. Sustainable practices not only help reduce environmental harm but can also open up new revenue streams for companies. Repurposing waste helps reduce landfill use, lowers carbon footprints, and creates jobs in new, innovative industries.

Consumers are increasingly looking for eco-conscious brands, and companies that adopt these sustainable solutions are putting effort into making real change. Whether it’s through bioplastics, bioenergy, or textiles, turning waste into value benefits everyone—from producers to consumers to the planet.

Conclusion

The next time you enjoy a fresh glass of pineapple juice, remember that the humble pineapple has much more to offer than just its sweet flavor. By embracing innovative sustainable practices, we can ensure that every part of the fruit is put to good use, minimizing waste and helping to protect our environment. Companies and startups around the world are leading the charge in turning waste into valuable products, setting the stage for a more sustainable future. And who knows? Maybe one day, canned pineapple juice manufacturers will be at the forefront of the global zero-waste movement, proving that even the waste of today can power the innovations of tomorrow.