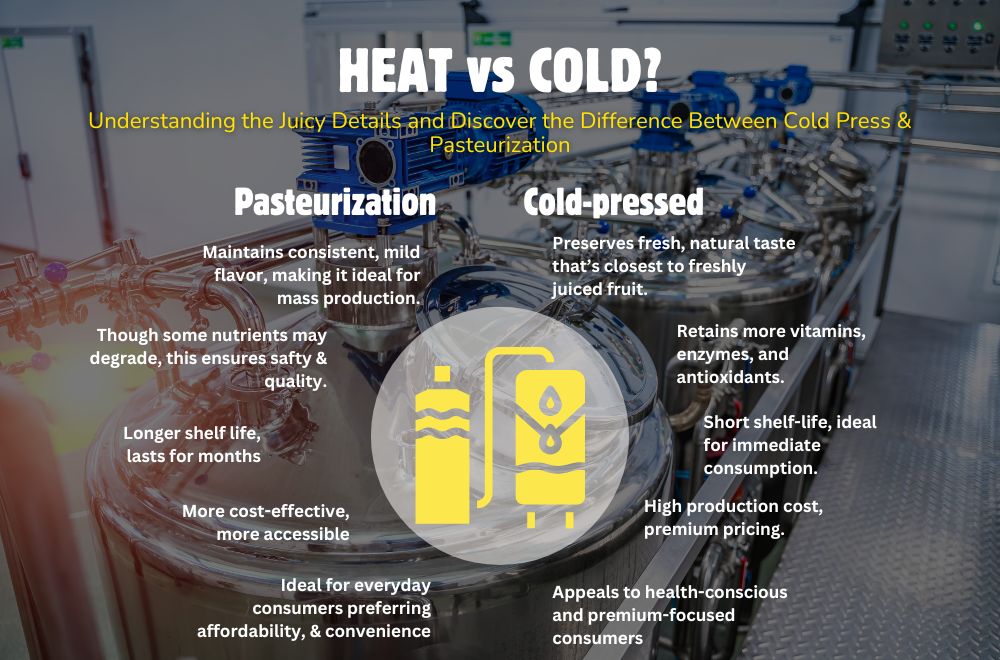

The juice industry has rapidly evolved over the years, and today, it caters to an increasingly health-conscious and informed consumer base. Among the most discussed topics in juice production are the methods used to process the juices: pasteurization and cold press. These processes significantly impact juice quality, flavor, shelf life, and nutritional value. Understanding these methods can help you make more informed decisions whether you’re a consumer, a retailer, or a juice juice supplier looking to meet market demands.

What is Pasteurization?

Juice Supplier Explaining Pasteurization

Pasteurization is a heat-treatment process designed to eliminate harmful bacteria and extend the shelf life of beverages. Named after Louis Pasteur, this technique has been a cornerstone of food safety since the 19th century. In juice production, it ensures consistency, stability, and safety for mass consumption, offering assurance of quality for products that reach millions worldwide.

Types of Pasteurization in Juice Production

High-Temperature Short Time (HTST): Heating juice to 161°F (72°C) for about 15 seconds, followed by rapid cooling. This method balances efficiency with the retention of key juice characteristics.

Ultra-Pasteurization (UP): Involves even higher temperatures (around 280°F or 138°C) for 2 seconds, significantly prolonging shelf life while slightly altering the natural flavor profile.

Flash Pasteurization: A quicker heat process that retains more of the juice’s natural taste compared to traditional methods, ensuring better preservation of flavor nuances.

Pros and Cons of Pasteurization

Pasteurization provides key benefits that have cemented its role in juice production. It significantly extends shelf life, making it ideal for mass production and global distribution. By eliminating harmful pathogens such as Salmonella and E. coli, it ensures food safety while delivering consistent product quality across large batches.

However, pasteurization has its limitations. The high heat used can degrade some natural nutrients, especially heat-sensitive vitamins like Vitamin C, reducing the juice’s nutritional value. Additionally, it can alter the juice’s taste and texture, making it less fresh than raw options. Despite these trade-offs, pasteurization remains essential for balancing safety, shelf stability, and scalability.

What is Cold Press?

Juice Supplier Explaining Cold Press

Cold press is a method of extracting juice without using heat. Fruits or vegetables are crushed and then pressed under high pressure to extract juice. The extracted juice is bottled immediately and, in many cases, preserved using a technique called High Pressure Processing (HPP).

HPP is a cold pasteurization method where bottled juices are placed in a high-pressure chamber and subjected to extreme pressures, typically ranging from 43,500 to 87,000 psi. By applying pressure evenly throughout the bottle, harmful pathogens like bacteria, yeast, and molds are effectively neutralized, ensuring food safety without sacrificing quality.

This technique significantly extends the shelf life of cold-pressed juices compared to untreated raw juice, often up to several weeks under refrigeration. Additionally, HPP eliminates the need for artificial preservatives or additives, making it an appealing option for health-conscious consumers.

Pros and Cons of Cold Press Juice

HPP offers a range of benefits that align with the growing demand for minimally processed, high-quality beverages. First, it preserves the fresh, natural flavor of cold-pressed juice by avoiding heat, ensuring the final product tastes as close as possible to freshly juiced produce. Nutritional value is another major advantage, as HPP retains more vitamins, enzymes, and antioxidants than traditional heat treatments, meeting the expectations of health-conscious consumers. Furthermore, HPP effectively eliminates harmful pathogens, such as bacteria, yeast, and mold, ensuring food safety without requiring artificial preservatives or additives. It also extends the shelf life of cold-pressed juices to several weeks under refrigeration, providing a balance between freshness and practicality for both suppliers and consumers.

However, the technique is not without drawbacks. The equipment required for HPP is highly specialized and expensive, leading to higher production costs that are often passed on to consumers in the form of premium pricing. Cold-pressed juices treated with HPP still have a shorter shelf life compared to pasteurized juices, necessitating refrigeration and quick consumption. This can limit distribution opportunities, especially for suppliers aiming to scale up operations or serve global markets. Additionally, while HPP supports high-quality small-batch production, it may not be as cost-effective or efficient for large-scale producers, presenting challenges for suppliers looking to meet both niche and mainstream demands.

What Juice Suppliers Offer Today

In a market increasingly shaped by health-conscious and sustainability-minded consumers, juice suppliers are adopting more innovative strategies to cater to diverse preferences. This diversification reflects the ongoing evolution of the industry and provides valuable insights into its future.

Pasteurized Juices: The Backbone of Mass Appeal

Pasteurized juices continue to dominate the shelves of supermarkets and convenience stores, favored for their affordability, extended shelf life, and large-scale production. These products meet the demands of busy families and on-the-go consumers, ensuring accessibility without sacrificing safety. According to juice suppliers, pasteurization remains the go-to choice for large-volume distributors aiming to balance cost-effectiveness with reliable quality.

Cold-Pressed Juices: The Premium Experience

On the other end of the spectrum, cold-pressed juices have carved out a niche among health-conscious and trend-savvy consumers. Found in premium grocery stores, boutique cafes, and online wellness platforms, these juices are prized for their fresh, vibrant flavors and nutrient retention. Industry experts note that this segment attracts customers willing to pay a premium for quality and transparency, particularly Millennials and Gen Z consumers prioritizing clean labels and artisanal processes. For suppliers, these juices signal a commitment to minimal processing, with High Pressure Processing (HPP) as a cornerstone for maintaining freshness without additives.

Bridging Markets with Hybrid Models

Recognizing the potential to serve both mainstream and niche audiences, many juice supplier now embrace hybrid strategies. By offering pasteurized juices alongside cold-pressed lines, they balance volume with exclusivity. Flash pasteurization, a technique combining heat efficiency with flavor preservation, is gaining momentum as a middle ground. This innovation allows brands to deliver fresher-tasting products with extended shelf lives, aligning with changing consumer expectations.

How to Choose Between Pasteurization and Cold Press

For Consumers

The choice between pasteurization and cold press comes down to what matters most to you. If convenience, affordability, and a longer shelf life suit your lifestyle, pasteurized juices are the ideal choice. They’re perfect for stocking up and enjoying at any time, providing a practical solution for busy days. On the other hand, if nutrition, raw flavors, and freshness are your top priorities, cold-pressed juices offer an unrivaled experience. Although they come with a premium price, every sip provides unprocessed goodness for those who value health above all.

For Retailers

Variety is essential in meeting the needs of a diverse customer base. Stocking pasteurized juices ensures that you cater to everyday shoppers who prefer cost-effective, reliable options. For your health-conscious customers, offering a dedicated section of cold-pressed juices can showcase your commitment to quality. These premium products will differentiate your store and appeal to the growing demand for natural, minimally processed items.

For Juice Supplier

Understanding your market is crucial for success. Pasteurization remains the standard for large-scale production, catering to a broad audience with affordable, long-lasting juices. However, investing in cold-pressed techniques opens doors to the premium market, where health-conscious consumers are willing to pay for quality. By balancing these two methods and exploring innovations like High Pressure Processing (HPP), you can position yourself as a leader serving diverse consumer preferences.

Conclusion

Understanding the difference between pasteurization and cold press can help juice supplier, retailers, and consumers make better choices based on their priorities. While pasteurization offers reliability, scalability, and affordability, cold pressing focuses on maximizing nutrition and delivering a fresh, premium experience.

As consumer awareness continues to rise, juice suppliers are innovating to offer the best of both worlds, ensuring a diverse market for everyone. Whether you prefer long-lasting convenience or the raw taste of fresh fruit, today’s juice suppliers are ready to meet your needs.